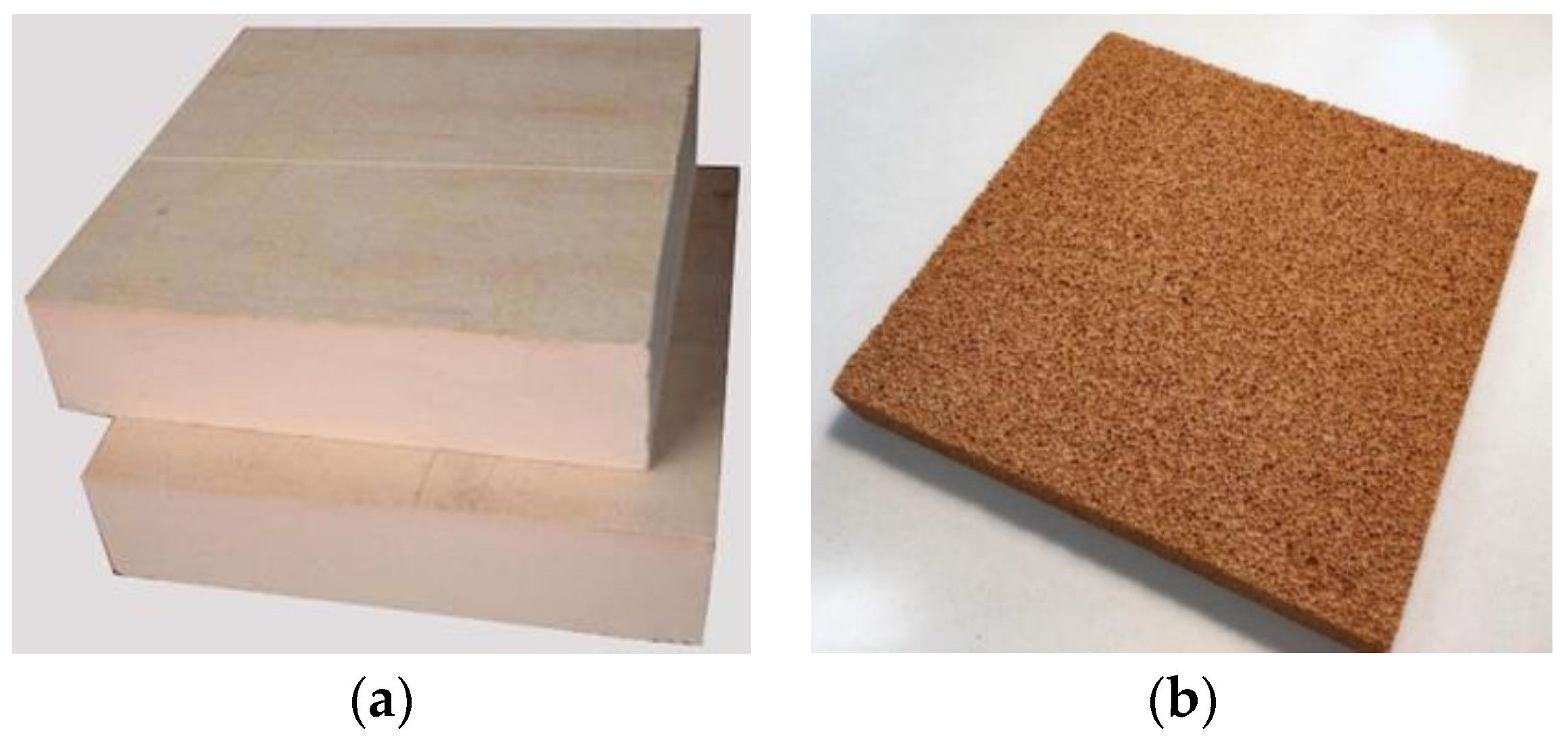

The first three are described below with information on their general properties and how they are produced.

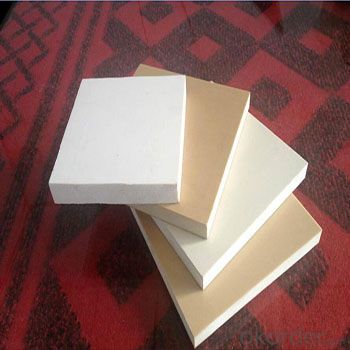

The environmental impact of phenolic foam insulation boards.

However if designers are to make informed decisions on material choices the environmental impact of the insulation should be considered and the payback period of the associated impacts evaluated.

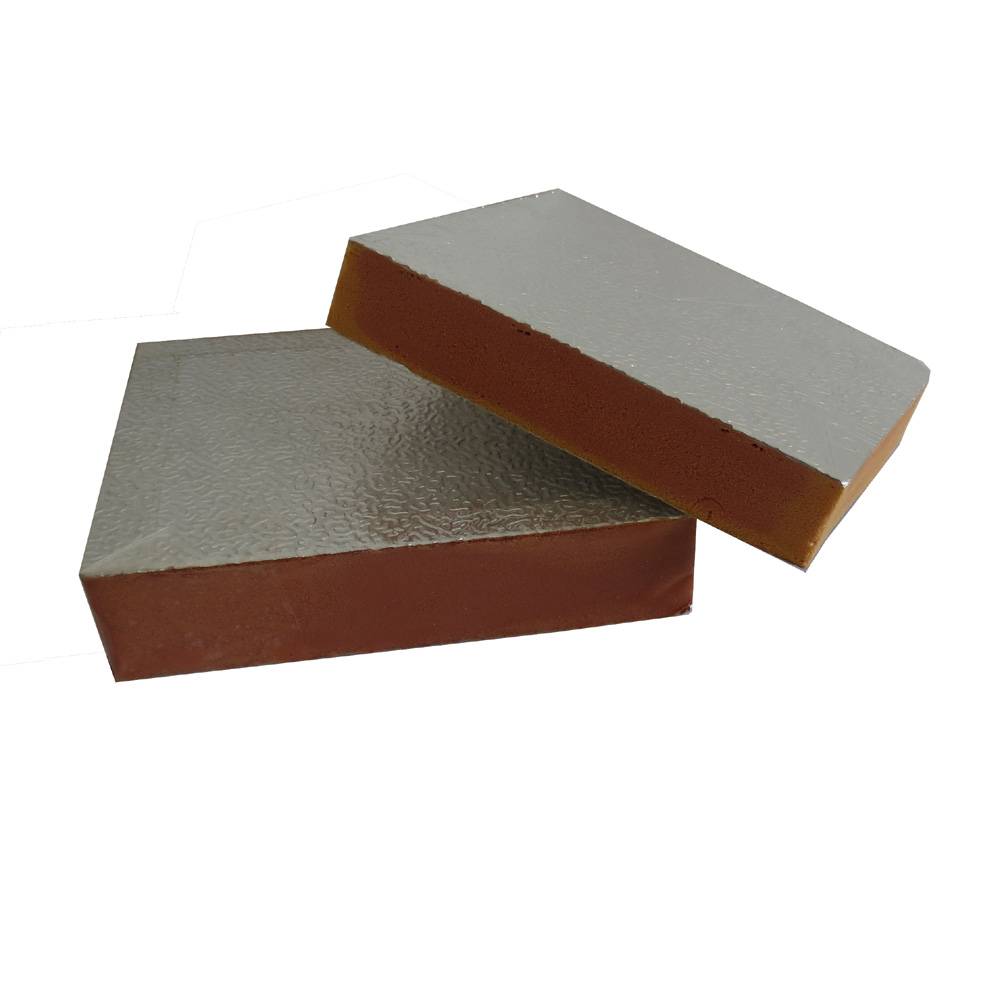

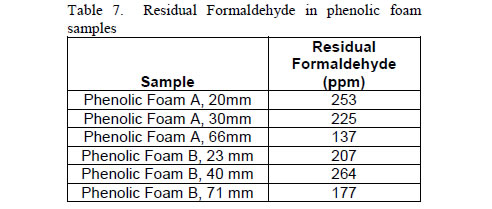

Phenolic foam is made from three main components.

Eps phenolic foam and pir boards are all derived from fossil fuel derivatives.

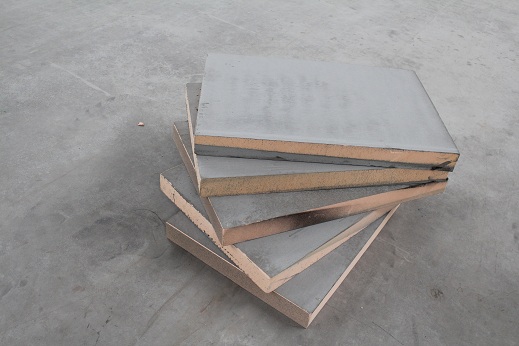

The use of external wall insulation is on the increase with phenolic foam being a popular insulation choice.

A full environmental impact comparison is made for eps rockwool and phenolic foam based on the functional unit.

Phenolic resin a blowing agent and an acid catalyst.

Phenolic foam insulation has a significant environmental impact exceeding that of other insulation materials.

However if designers are to make informed decisions on material choices the environmental impact of the insulation should be considered and the payback period of the associated impacts evaluated.

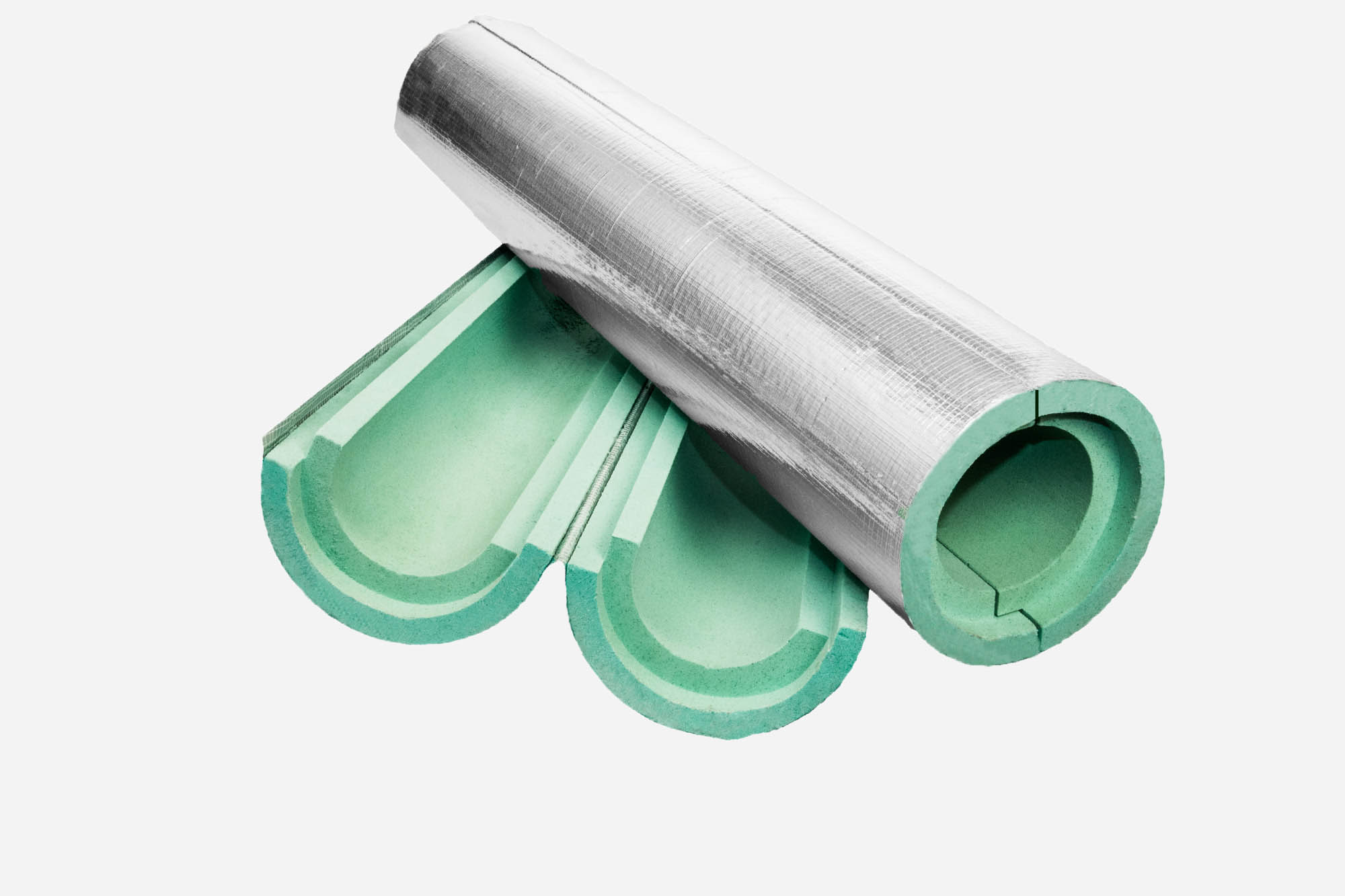

There are several major types of rigid foam insulation including polyiso cyanurate which is a type of polyurethane extruded polystyrene phenolic foam and expanded polystyrene eps.

Continual improvements in the formulations of phenolic foam board insulation products may overcome these drawbacks.

There is a lack of information for phenolic foam insulation.

In contrast mineral wool is made from volcanic diabase rock and woodfibre board principally uses waste soft wood offcuts from sawmills all the materials are formed into rigid boards that can be used for external wall insulation but could also be used in different retrofit applications such internal wall insulation.

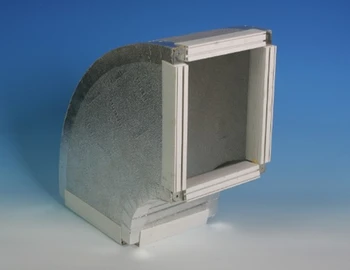

Facings on the foam insulating board can also help but at the time of the original solar age article august 1984 no one had successfully foamed phenolics between foil facings.

A range of data sources are used ecoinvent 24 for eps and rockwool densley.

Environmental impact estimates for phenolic foam insulation boards.

Properly applied phenolic insulation foam according to the epfa meets or exceeds international building insulation and fire regulations.

Significant amounts of petroleum and natural gas must be burned during the manufacturing and refining processes though the insulation industry has ceased to use chlorofluorocarbons cfcs in the manufacture of foam insulation products.

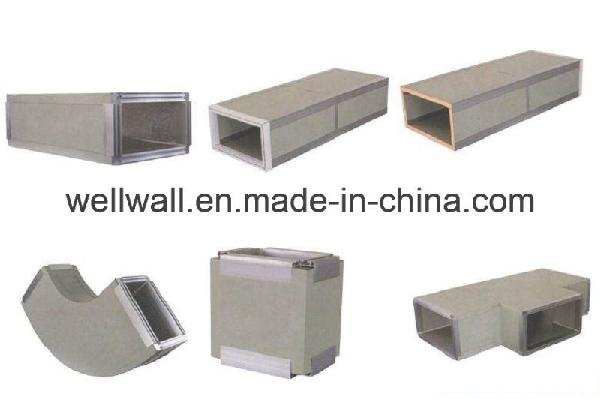

Phenolic foam insulation makes exceptional fire doors and panels because of both its low flame and smoke reaction to fire.

3 methodology this work evaluates whole building performance of retrofitted homes.

A number of additives can also be utilised to develop specific properties within the foam.

Provision of this information will allow environmental impact comparisons of different external wall insulation choices and environmental payback estimates for this and future projects.

Phenolic insulation has low flame and smoke reaction to fire.

There are patents and other information.

Environmental impacts of phenolic foam that will allow others to make informed decisions on insulation choices.