Electrically thermally conductive 1 part silver epoxy heat cure high temp 325f electro bond 04 is a single component heat curing conductive epoxy polymer that was designed for e.

Thermally conductive electrically insulating coating.

Fully unifying the advantages of the thermally conductive three layer electrically insulating film and an antistatic film the ordered five layer thermally conductive film 7 04 w m 1 k 1 with 8 wt fillers exhibits a comprehensive performance with electrically insulating and antistatic properties which simultaneously has an excellent.

Environmentally resistant provides good resistance to water and a wide variety of chemicals.

Thermally conductive electrically insulating conformal coating.

Formulating thermally conductive compounds.

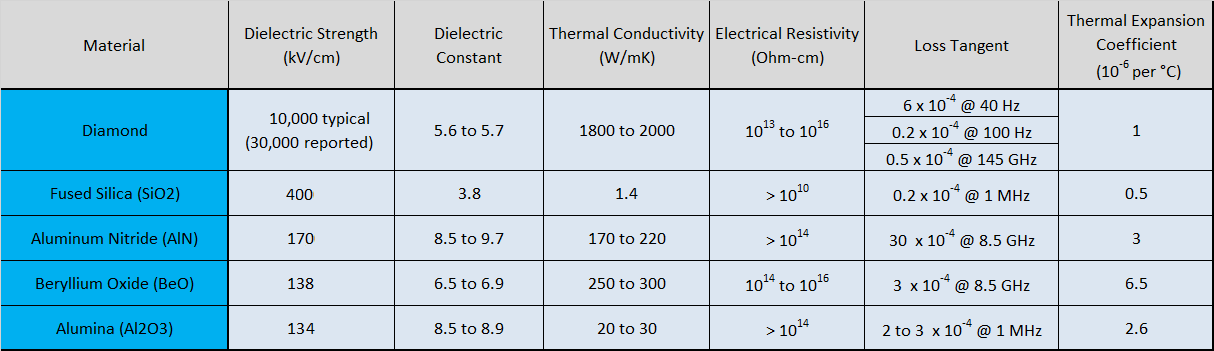

A a coatings thermal spraying process to achieve electrical insulation.

Specializes in thermally conductive electrically insulating epoxy and has been doing so for the last 45 years.

General purpose thermally conductive electrically insulating fire retardant encapsulant meets ul 94 v 0.

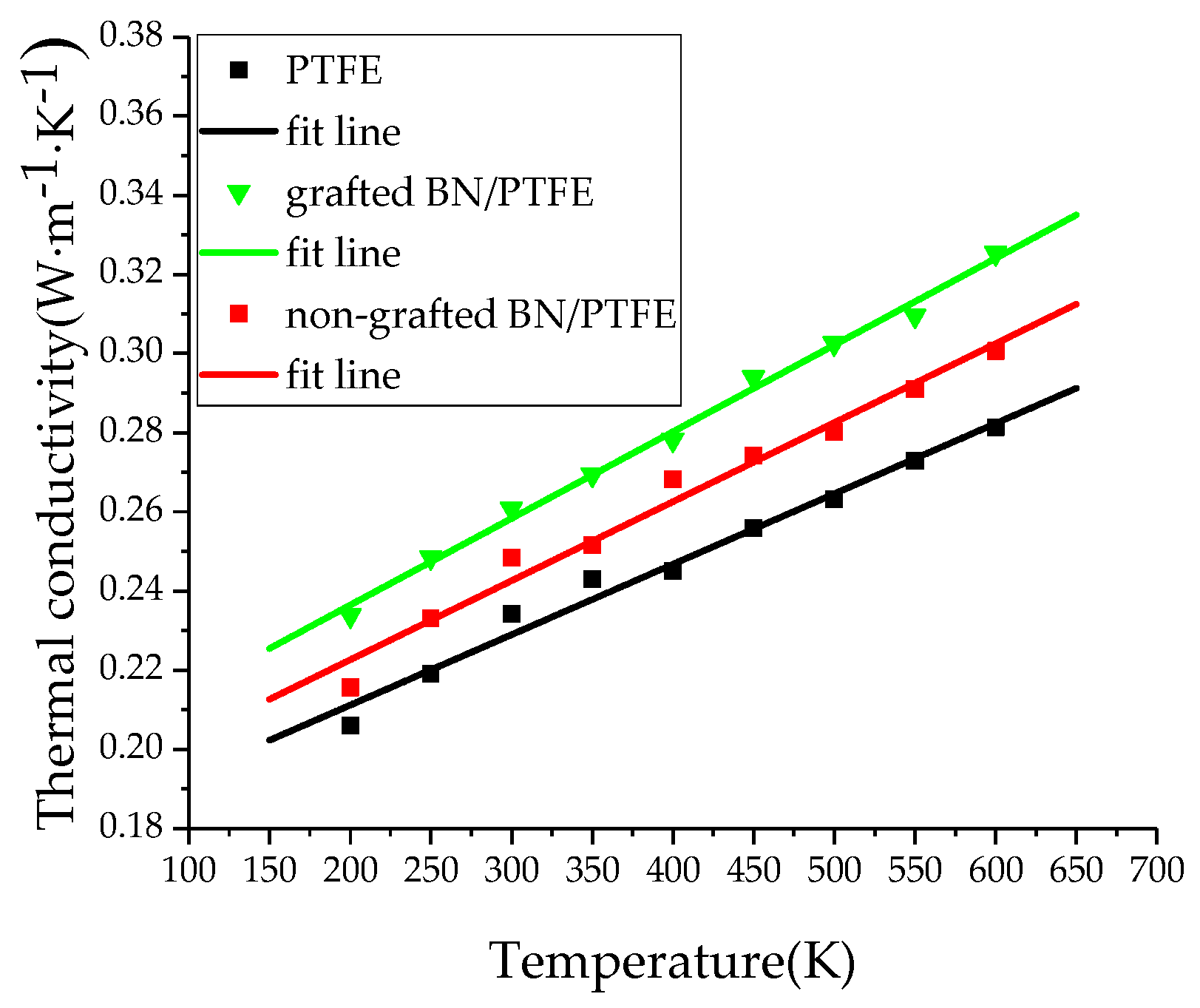

Thermal conductivity of a typical unfilled epoxy system has a very low value of 0 14 w m k.

Thermally conductive but electrically insulating polymer composites are highly desired for thermal management applications because of their ease of processing light weight and low cost.

This key property can be increased by adding metallic or ceramic fillers to the adhesive formulation.

Thermally conductive electrically insulating low thermal expansion adhesive epoxy adhesive.

Thermally conductive epoxy cast coat inc.

Our aluminum filled system is widely used for the assembly of both fin bonded and folded fin heat sinks as well as cooling plates.

When it comes to materials engineering a a coatings has been recognized as one of the industry leaders because over the years we are able to develop high quality dielectric coatings via our thermal spraying coating processes.

Low viscosity maintains low viscosity allowing easy.

A a coatings is a surface engineering firm committed to providing industry specific coating solutions and we can apply a vast selection of materials via the thermal spray coatings process to enhance electrical conductivity in different types of substrates.

High thermal conductivity provides high electrical insulation with exceptionally good heat transfer.

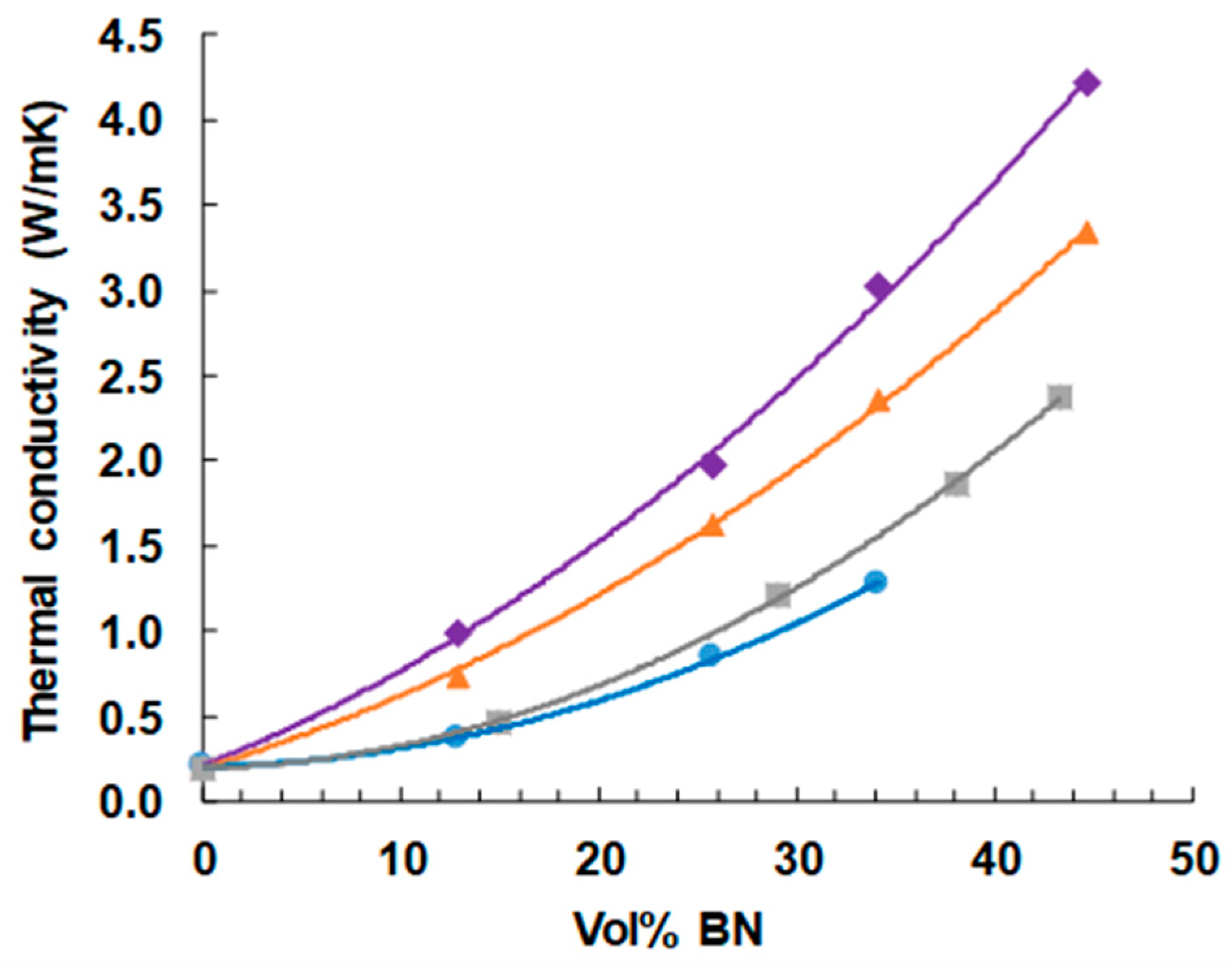

The type of filler concentration of particles their size and shape will determine the thermal.

Broad temperature range can be used on parts and devices that experience operating temperatures from 65 c to 130 c.

Thermo bond 110 is flame retardant and is designed to meet the rigid requirement of ul 94 v0.

.jpg)

.jpg)